Laboratory HOT AIR OVEN

Hot Air Oven

A Hot Air Oven is a sterilizing machine which is used for sterilizing the instruments with the help of dry heat. It is also known as dry heat sterilization. A laboratory hot air oven is used for heating products at uniform temperatures. The airflow with heat from the Hot Air Oven by fusion product controls the humidity level by removing moisture. Microorganisms and bacterial spores can be simply destroyed by the Laboratory hot air ovens with precise temperatures. To kill microorganisms an oxidation method is involved, This process is used to kill microorganisms and they are oxidized.

It is mainly applicable to samples that are heat resistant. Successful sterilization can as it were to be accomplished when a suitable temperature and holding time are chosen depending on the type of microorganisms being sterilized. Louis Pasteur evolved the process of dry heat by using a Hot Air Oven. These air convection ovens have applications in many fields e.g. laboratory, medical, pharmaceutical and textile industries.

Model ELI- HAO

Principle of Laboratory Hot Air Oven.

Hot Air Oven works on conduction and radiation. The heat is passed inside the next and absorbed by outside items in the process of conduction. To sterilize materials in hot air ovens 170 degrees Celsius for 30 minutes, 160 degrees Celsius for 60 minutes, and 150 degrees Celsius for 150 minutes are commonly used temperatures and times.

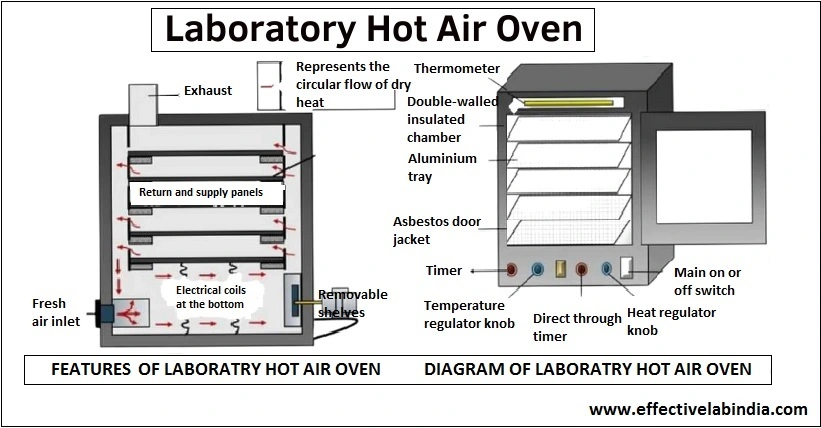

Salient Features of Hot Air Oven

- External cabinet: It covers the internal chamber and is made of stainless steel.

- Glass wool insulation: The internal and external chambers are filled with glass wool which provides insulation to the oven.

- Inner chamber: To support long-lasting operations it is also made of stainless steel and consists of slots.

- Tubular air Heaters: For sterilization inside the chamber for heat production tubular air heaters are present.

- Motor-driven blower: For equal circulation of air hot air oven consists of motor motor-driven blower.

- Temperature sensor: Inside the oven chambers the temperature is regulated and maintained.

- Tray slots: They are made of aluminium and in the inner chamber on these trays materials are kept.

- load indicator: How much load the oven consists of is indicated by the load indicator.

- PID digital temperature controller cum indicator.

- Temperature control via PT-100 sensor

- Extremely accurate test results at constant chamber temperatures

- Maximum Thermal Efficiency through the use of insulation.

- Advanced PID temperature controller with digital microprocessor

- Touch controls with feathers

- Self-adjusting SSR-based output controls with advanced PID controllers

- Luminous graphic monochrome LCD display displaying test values and graphics for easy user-interaction

- Test process completion for alarm output signal

- Situation Data recording up to 4 Lacs with date and time stamping (2GB memory)

- Simple graphical menu-driven system

- Superior quality imported glass wool for insulation

- Programmable soak timer built-in

- Display: Digital monochrome graphic LCD display

- Dimensions: 18″ x 18″ x 18″ / 455 x 455 x 455 mm

- Precision: ± 2ºC

- USB / RS-232 communication port (through converter)

- Power: 220V, 50 Hz, single phase, 15 amps

- Range of the Timer: 99 hours: 59 minutes

- Maximum temperature: 250ºC (higher temperatures available upon request)

- 0. 1ºC is the least count/resolution.

Get in Touch

The Laboratory Hot Air Oven can be utilized to sterilize materials materials that don’t capture fire, soften, or alter shapes under high temperatures. Hot air ovens can sterilize glassware e.g. Petri dishes, flasks, pipettes, and test tubes, powder like starch, zinc oxide and sulfadiazine, oil-containing materials, metal apparatus scissors, scalpels and blades.

Materials like rubber-containing objects, plastic objects and dressing used in surgeries are not sterilized by Hot Air Oven.

Benefits of Laboratory Hot Air Oven.

- It doesn’t require water to sterilize.

- It can operate at higher temperatures than autoclave and faster.

- Bacterial endotoxins are killed by it.

- For sterilization of oil and powder, it’s the only method.

- It is a less time-consuming process.

- It is temperate and safe.

- It is fitted within the lab environment.

- Its operating process is very simple.

- Sterilization occurs quickly and effectively.

- Cross-contamination is also prevented by using a hot air oven.

Hot Air Oven Diagram and Features

Our Related Products

Box Compression Tester

Peel Seal Bond Strength Tester

TP 800 Portable spectrophotometer

Co- Efficient of Friction Tester

Bursting Strength Tester

GSM Round Cutter Machine

Color Matching Cabinet

Cobb Sizing Tester

Laboratory Heat Sealer

GSM Balance- Digital Model

Edge Crush Tester

Tensile Testing Machine