A specialised testing machine used to simulate the effects of materials exposed to saltwater is called a salt spray chamber. Experts and manufacturers use this to evaluate materials and product performance. They focus on challenging conditions, especially rust and corrosion. It is a vital instrument for businesses where environmental resistance and durability are important.

How a Salt Spray Chamber Works

Salt spray chambers create an environment that simulates the corrosive effects of saltwater exposure. It uses a saltwater solution that is atomised and sprayed on samples in a lab environment. To give precise and trustworthy testing, the chamber keeps its temperature and humidity levels constant.

Types of Salt Spray Chambers

Standard Salt Spray Test Chambers: Standard types for general metal corrosion testing.

Cyclic Salt Spray Chambers: Give realistic simulations of temperature fluctuations and salt spray. A Cyclic Corrosion Test Chamber combines several environmental elements to replicate real-world environmental conditions. This chamber replicates the intricate nature of natural corrosion processes. It cycles between different environments, such as humidity, temperature cycles, and salt spray.

High-Temperature Salt Spray Chambers: Made to withstand extremely high or low temperatures to test high-performance materials.

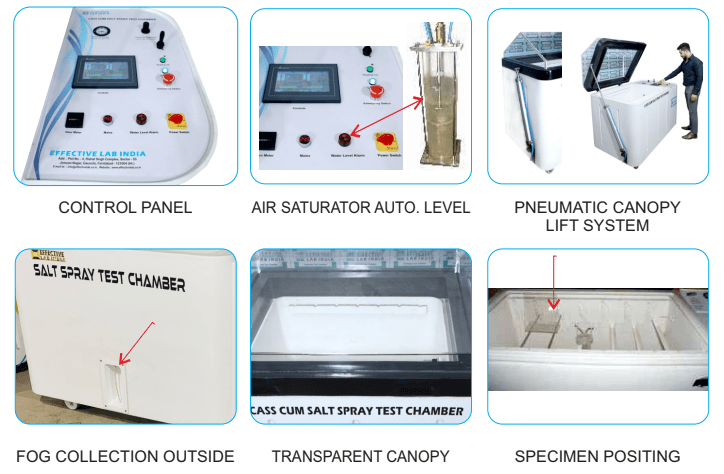

CASS Cum Salt Spray Chamber: For accelerated salt spray testing with a copper accelerated solution, we use this chamber. This chamber is made especially for this purpose. For a more intense and quick simulation of corrosive effects, it combines the traditional salt spray test. It also adds an accelerated element.

Preparing for the Test

Make sure your salt spray Test chamber is configured properly before conducting a test. Verify that every part—including the temperature controls, atomisers, and saline solution—is operating as intended. For setup and calibration, refer to the manufacturer’s instructions.

Start the test by placing your samples inside the chamber. For a certain amount of time, the samples will be sprayed. A fine mist of saline solution will be applied in the chamber. Make sure the conditions in the chamber stay steady throughout this period by keeping an eye on them.

Keep thorough documentation of the test limits and findings. Note any alterations to the samples’ appearance, like discolouration or rust growth. Later on, this information will be useful for analyzing the outcomes.

When Is the Best Time to Use a Salt Spray Chamber?

During Product Development

Timing: Salt spray testing is best done in the early phases of product development. Testing early designs or prototypes can identify any flaws and enable changes before mass production. This proactive strategy aids in the creation of more durable and dependable products.

Why: By detecting corrosion problems early in the development process, materials and coatings are improved. This improves product performance and increases customer satisfaction.

For Quality Control

Timing: Throughout the production process, regular intervals are best. Quality control tests are used at several phases to make sure that every batch satisfies the requirements. These stages include manufacturing, post-production, and pre-shipment.

Why: Regular quality control keeps products consistent and guards against flaws that might result from changes in the production process.

Before Product Launch

Timing: Testing a new product just before release ensures that it satisfies industry requirements and functions well in actual use. To prevent expensive recalls or consumer complaints, this last inspection is essential.

Why: A pre-launch test verifies that the product can withstand the challenges it will meet in the market. It helps to safeguard the reputation of your brand. It also ensures consumer happiness.

Recommendations for Choosing the Right Chamber

Consider your unique testing needs, such as the kinds of scenarios you must replicate and the turnaround time for findings. For the most efficient corrosion testing, select the chamber that most closely matches your requirements. Modern solutions for accurate and trustworthy corrosion testing are provided by Effective Lab India, a leading manufacturer of high-performance salt spray chambers. Their leading-edge chambers promise precise outcomes, making them the best option for quality assurance across a range of sectors.

Conclusion

When using a salt spray chamber, it’s important to prioritise accurate calibration. Reliable sample preparation is crucial. Routine maintenance is needed to achieve maximum efficiency. Ensuring long-term durability and enhancing product quality need precise testing and analysis.

Final Thoughts

Effective use of a salt spray chamber greatly improves your rust-proofing efforts. It can also assist your company in producing dependable, high-quality goods. You can maintain an advantage in a cutthroat industry by adhering to best practices and constantly improving your testing procedures.