Metamerism is a common problem faced by the manufacturers of colour products. It creates different looks of products under different conditions of lighting. To prevent this problem, manufacturers need to select a good colour for their products and test the look of their products under various lighting conditions. This prevention is because the products look astonishing in every type of light.

So, manufacturers can test the colour consistency of their products with the help of a machine known as a colour-matching cabinet.

It helps in reducing the metamersim of products.

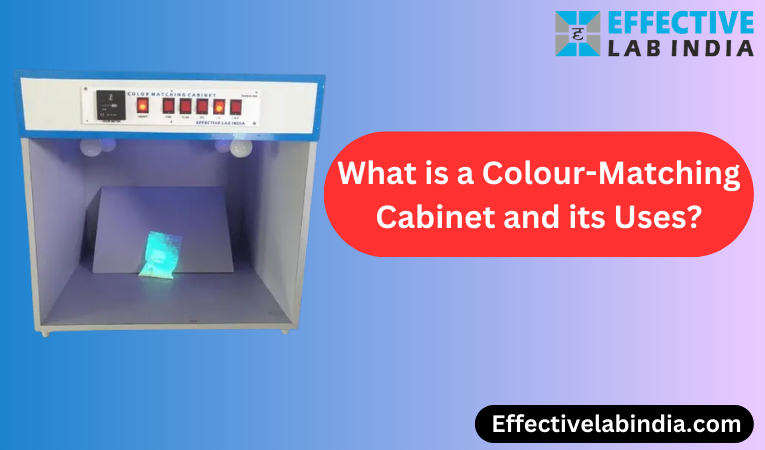

Hence, a colour matching cabinet is a reliable tool for testing different products’ quality and colour consistency. It is designed to match colour accurately so that the products can look best on site. Also, you can test colour consistency under different lighting conditions with the help of a built-in light source present in this instrument. It is structured with good materials and is well-built so it can last for years.

In a colour-matching cabinet, a controlled and standardized lighting environment determines the colour difference between products. Hence, from the difference, the colour consistency can be determined.

What is a colour-matching cabinet used for?

A colour matching cabinet is used in laboratories and different industries for the assessment of colours in different products. It is used in industries where colour assessment is important.

It is most commonly used in textiles, printing and manufacturing industries for evaluation of colours. With the help of this instrument, manufacturers can ensure the colour consistency of their products.

In industries, it is used for different purposes such as.

- Quality Control

- Colour Evaluation

- Colour Assessment

- Colour Matching

Hence it is a versatile tool for maintaining the accuracy of colurs in different industries.

How does a colour-matching cabinet work?

In a colour-matching cabinet, a standardized lighting condition is created. This condition evaluates the accuracy of colours in different materials.

For simulating different lighting environments, multiple light sources such as fluorescent, and incandescent are placed in this instrument.

Different colour temperatures are available for these light sources which helps assess colour in different conditions of light.

The quality of colour of different materials can be checked by placing the material under these lighting sources in a colour-matching cabinet.

What is the best light source for colour matching?

A standard light source called D-65 is the best light source used for a matching cabinet. It is used in the applications of plastics, paints, textiles and manufacturing products. Green and Red are subdued and blue accentuates with it. In colour measurement instruments, D65 is also used as a primary source of light.

What is the colour-matching process in the textile industry?

Colour matching is an important process for determining the accuracy and consistency of colours in the textile industry. The process of colour matching in the textile industry is listed below.

•Specification of colour: First receive a specific colour from a designer or client.

•Formulation: After specifications, the colour is formulated with the help of a technician or colour experts. The type of fabric or method of dying is considered a factor in this.

•Lab Dying: By using the proposed dye recipe, the formulated colour is dyed in the lab. Technicians match the desired share with its help.

•Evaluation of colour: After that, the dyed fabric is evaluated with the help of a colour-matching cabinet. In this D65 light source is used. Colour is evaluated and necessary adjustments are made (if applicable).

•Production: After achieving the desired colour, the process is scaled up for production.

•Quality control: Quality control measures are put throughout the process of production. It is for ensuring the consistency of colours.

In addition, Regular samples are taken from the production batch and are compared with the matched colour for verifying the colour maintenance.

Hence, a textile industry can achieve accurate colour matching with the help of the above process and the fabrics are produced with specific specifications of the desired colour.